Specialty Machining Topics introduces a variety of important manufacturing processes and concepts that go beyond basic milling and turning. These include both conventional methods—like threading, grinding, drilling, and sawing—and more advanced technologies such as CNC (Computer Numerical Control) and EDM (Electrical Discharge Machining). The section also covers essential topics like cutting fluids and precision holemaking, giving students exposure to the broader range of tools and techniques used in modern machining.

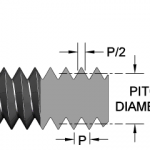

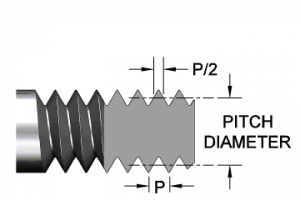

Screw Threads & Threading Operations

Screw Threads and Threading Operations covers the principles, terminology, and methods used to produce threaded features—an essential part of most mechanical assemblies. Threads allow parts to be fastened, adjusted, or disassembled and are found in everything from bolts and nuts to precision lead screws. This section introduces the different types of threads, how they are...

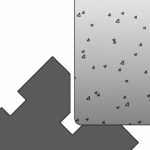

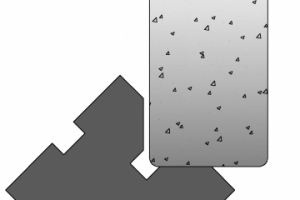

Grinding & Abrasive Machining

Grinding & Abrasive Machining focuses on material removal processes that use abrasive particles instead of cutting edges. These methods are essential for producing fine finishes, tight tolerances, and precise shapes—often in applications where traditional machining would be too rough or inaccurate. This section introduces the types of grinding machines, common abrasives, and how grinding differs...

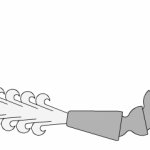

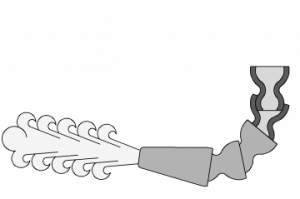

Cutting Fluids

Cutting Fluids introduces the role of liquids and coolants used during machining to improve performance, extend tool life, and protect both the workpiece and the machine. These fluids serve multiple purposes: they reduce heat, minimize friction, flush away chips, and help achieve better surface finishes. This section covers the different types of cutting fluids—such as...

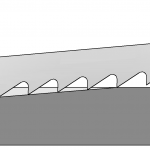

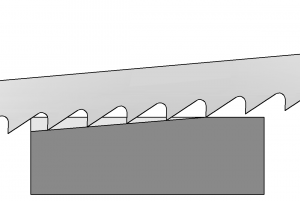

Sawing, Broaching & Filing

Sawing, Broaching, & Filing introduces machining processes that use groups or rows of cutting teeth to remove material in a controlled manner. Though simpler than milling or turning, these methods are important for rough cutting, shaping, or finishing parts. Sawing is commonly used for separating material quickly, while broaching uses a series of progressively larger...

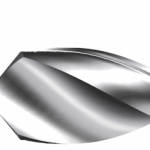

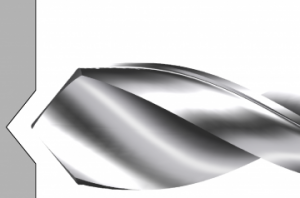

Drilling & Holemaking

Drilling and Holemaking covers the fundamental processes used to create and refine holes—one of the most common features in machined parts. These operations typically involve multi-point cutting tools, such as twist drills, which remove material to form a cylindrical opening. Beyond simple drilling, holemaking includes a range of secondary processes like reaming, countersinking, counterboring, and...

Screw Threads & Threading Operations

Screw Threads and Threading Operations covers the principles, terminology, and methods used to produce...

Grinding & Abrasive Machining

Grinding & Abrasive Machining focuses on material removal processes that use abrasive particles...

Cutting Fluids

Cutting Fluids introduces the role of liquids and coolants used during machining to improve performance,...

Sawing, Broaching & Filing

Sawing, Broaching, & Filing introduces machining processes that use groups or rows of cutting teeth...

Drilling & Holemaking

Drilling and Holemaking covers the fundamental processes used to create and refine holes—one of the m...