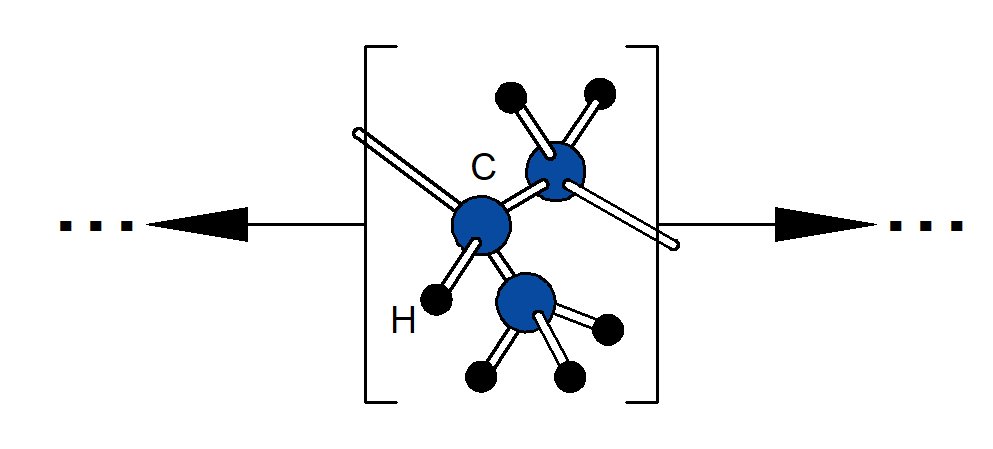

Polypropylene (PP) is a thermoplastic polymer derived from propylene monomers and characterized by a hydrocarbon backbone with a methyl (–CH₃) side group on alternating carbon atoms. This side group limits chain mobility compared to polyethylene, resulting in a material with greater stiffness, higher softening temperature, and improved resistance to deformation under moderate heat. Polypropylene is semi-crystalline, and its balance of rigidity and toughness makes it suitable for components that must retain shape while still allowing limited elastic flexing.

From a product design perspective, polypropylene is valued for its low density, good fatigue resistance, and excellent chemical and moisture resistance. One of its most notable uses is in molded “living hinges,” where thin sections of material can flex repeatedly without cracking, making it common in flip-top caps, storage containers, and integral hinges in consumer products. The material also offers good electrical insulation properties and maintains performance in environments exposed to water, detergents, and many common chemicals, which contributes to its widespread use in household goods, medical disposables, and automotive interior components.

Polypropylene is readily processed by injection molding, extrusion, and thermoforming, allowing efficient production of thin-walled parts and complex geometries. Its relatively low melting temperature compared to many engineering plastics simplifies processing and reduces energy requirements in high-volume manufacturing. For designers, polypropylene is often selected when a lightweight, chemically resistant, and fatigue-tolerant material is needed, particularly in applications involving repeated flexing, snap-fit features, or exposure to moisture.