Manufacturing and machining are foundational pillars of modern industry, enabling the transformation of raw materials into functional products and components. Manufacturing refers broadly to the processes used to produce goods, encompassing everything from manual craftsmanship to high-tech automated production lines. Machining, a vital subset of manufacturing, focuses specifically on removing material from a workpiece to...

Understanding metal classification, metallurgy, and heat treatment is fundamental to selecting and working with materials in engineering and manufacturing. Metals are broadly categorized based on their composition and properties—such as ferrous and nonferrous types—each with distinct strengths, weaknesses, and applications. This classification helps guide decisions about which materials are best suited for particular parts or...

Machining processes encompass a wide range of manufacturing methods that remove material from a workpiece to achieve the desired shape, surface finish, and dimensional accuracy. These processes rely on power-driven machine tools and cutting tools to shear material in a controlled manner. Machining plays a central role in modern manufacturing, particularly when precision and repeatability...

This series of videos was created for the course TECH 1711 -Manufacturing Processes I. The video series is an introduction to machining. It describes the process of turning raw materials into a finished product. TECH 1711 Hammer Project 2021 (PDF Version)Download Machining Lab VideosPart 1 – Safety in the Machine Shop Part 2 – Machining...

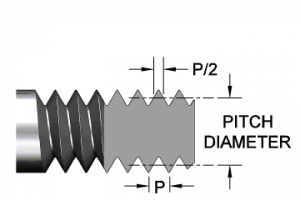

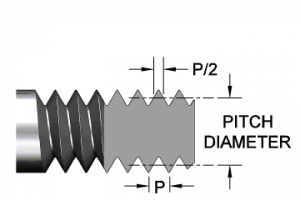

Specialty Machining Topics introduces a variety of important manufacturing processes and concepts that go beyond basic milling and turning. These include both conventional methods—like threading, grinding, drilling, and sawing—and more advanced technologies such as CNC (Computer Numerical Control) and EDM (Electrical Discharge Machining). The section also covers essential topics like cutting fluids and precision holemaking,...

Manufacturing and machining are foundational pillars of modern industry, enabling the transformation...

Machine tools are power-driven devices used to shape or finish metal and other materials by cutting,...

Measurement and metrology are essential to ensuring the accuracy, quality, and functionality of engineered...

Machine shop safety is critical to protecting individuals and maintaining a productive working environment....

Understanding metal classification, metallurgy, and heat treatment is fundamental to selecting and working...

Metals are a class of materials valued for their strength, durability, and thermal and electrical conductivity....

Commercially important metals are those that play a vital role in industry due to their availability,...

Phase diagrams are graphical tools used to understand how metals and alloys behave under different temperature...

The iron-carbon system is one of the most important alloy systems in engineering, forming the basis...

Heat treating of ferrous metals involves controlled heating and cooling processes used to alter the...